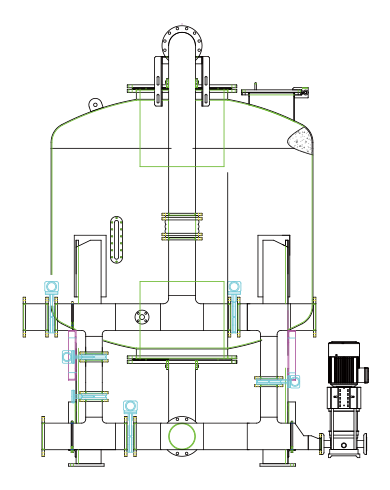

Cubic Fiber Filter

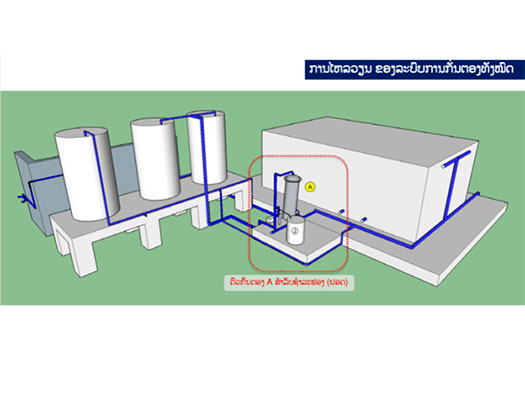

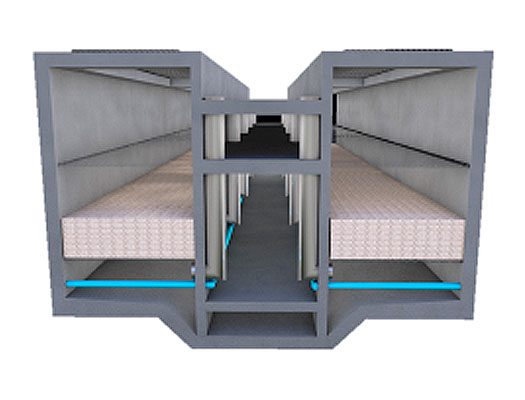

The filtration device is applied in various areas including residential, industrial, and agriculture and fisheries to contribute to water quality improvement and the reuse of water resources boasts universal applicability with its small size and light weight.

Overview

Feature

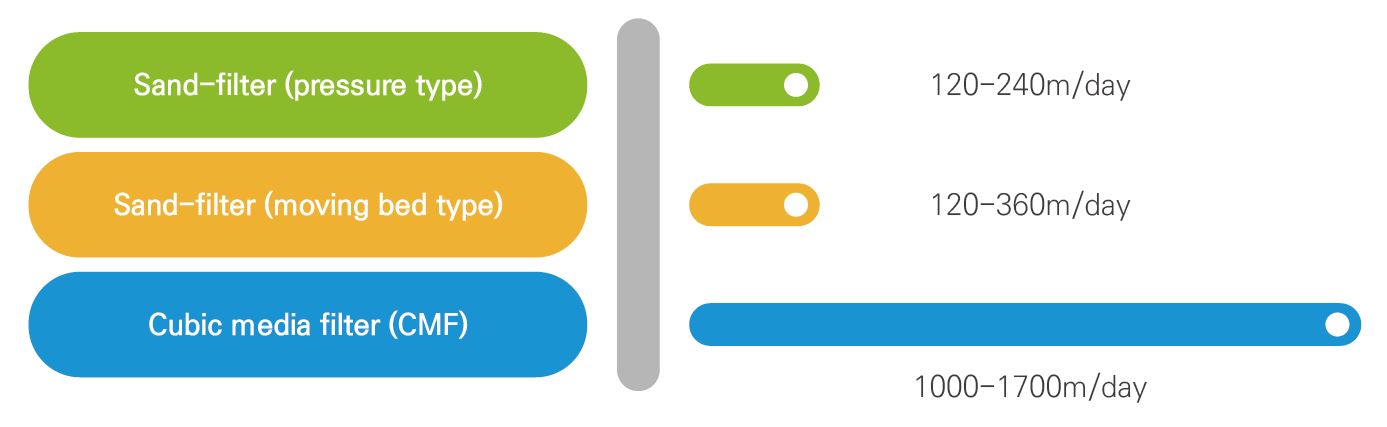

| Sortation | Feature | SAND |

|---|---|---|

| Filtration Flow | up-flow : Down Flow Operating pressure : 2 bar 이하 | 5~8 bar |

| Cleaning method | Clean through stirring Cleaning Time : 15Min | amount : 1% | Backwashing 40Min 5% |

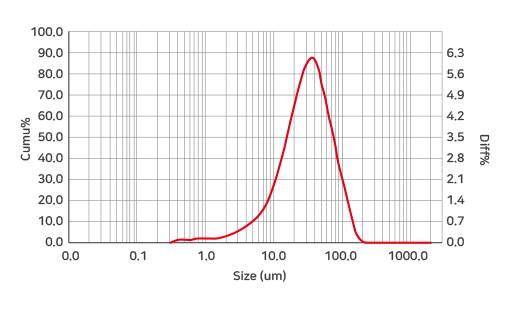

| Speed, Efficiency | LV : 70 m/hr 10 ㎛ , 90% | 10~15 20~30 ㎛, 70% |

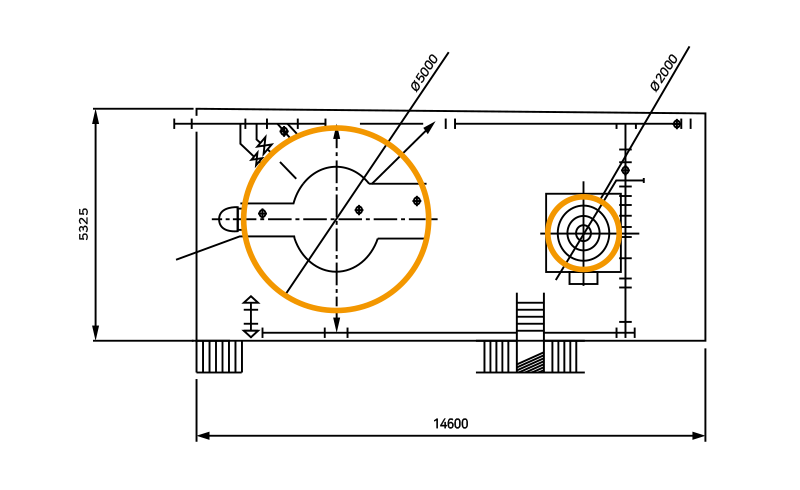

| Device size | 100 ㎥/hr | weight:2.5 Ton | Φ : 1500 | 21 Ton Φ : 3000 |

Characteristics of CFF

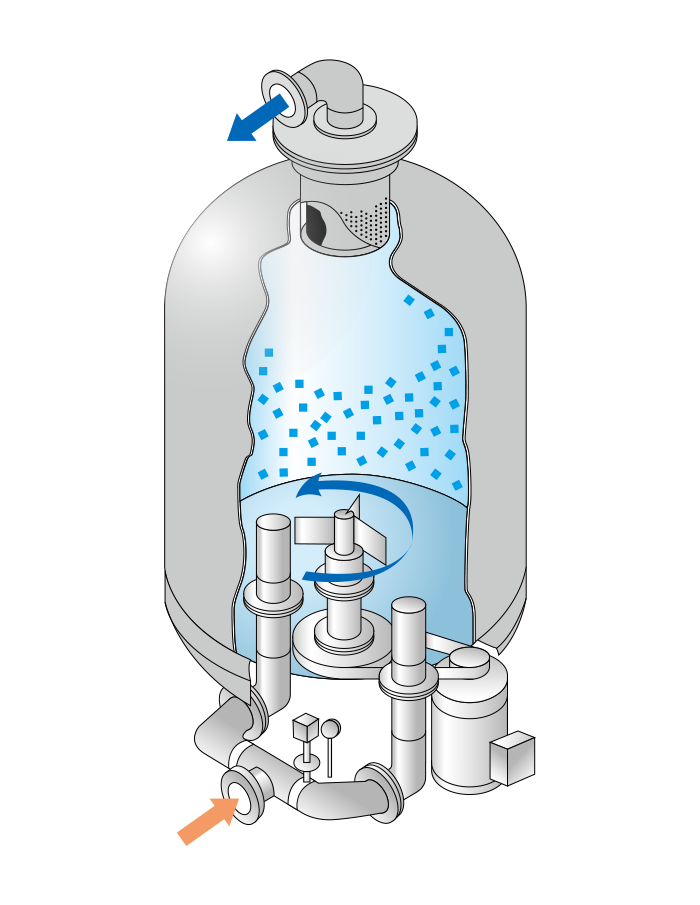

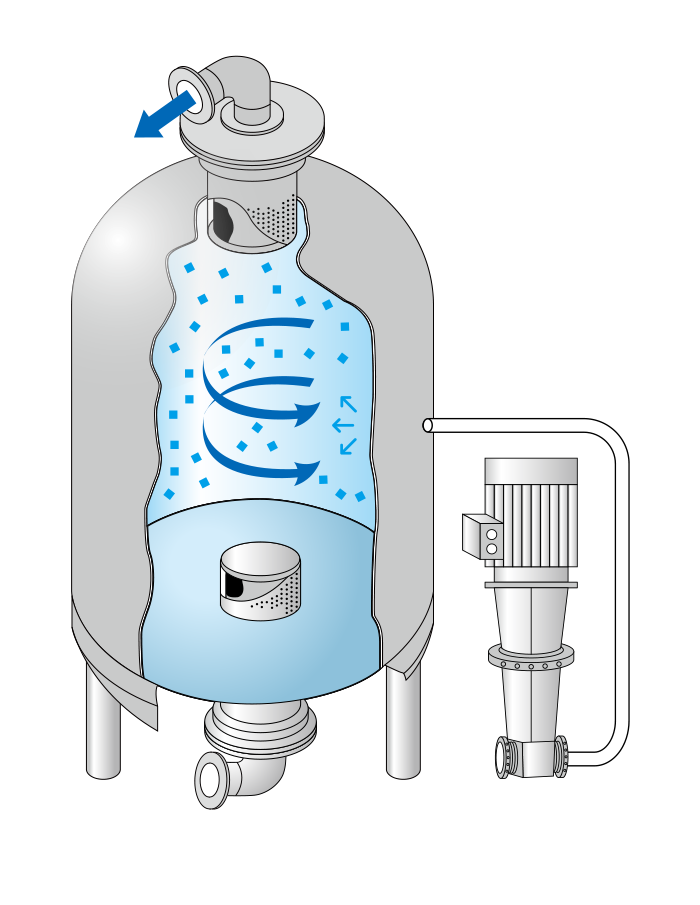

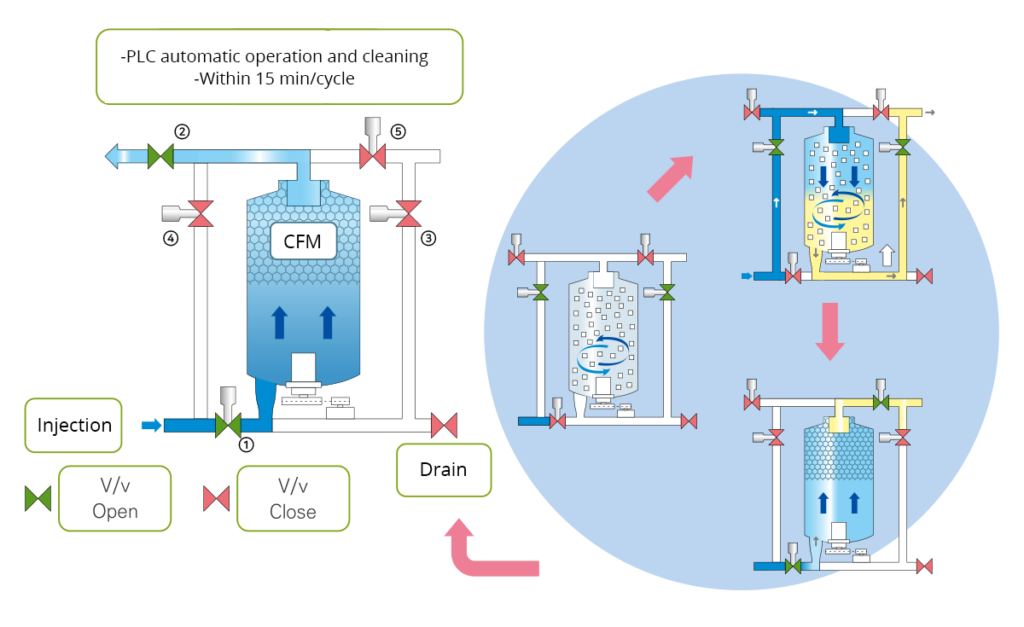

▣ Clean through stirring

– The filtration process which is included in the automated cleaning process according to the pressure increased through collection and operation duration.

– After the cleaning of about 15 minutes in the order of stirring, stirring and drain, and rinsing, the filtration process resumes.

– The quantity of water required for cleaning and the abrasion and loss of filter media are minimized and fully automatic cleaning or fine customization to actual conditions is available.

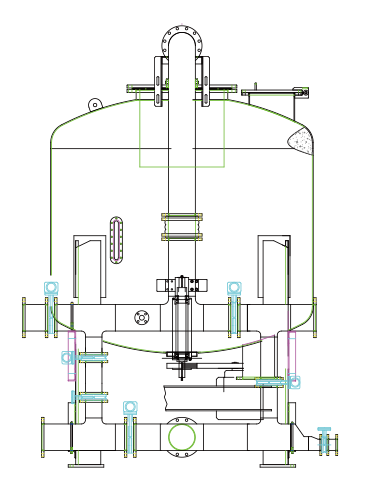

The capacity and specifications of the media filter

| Type | CFF-600 | CFF-850 | CFF-1150 | CFF-1600 | CFF-2000 | CFF-2600 | |

|---|---|---|---|---|---|---|---|

| Filtration area (㎡) | 0.28 | 0.56 | 1.0 | 2.0 | 3.1 | 5.3 | |

| Handling capacity (㎥/hr) | 20 | 40 | 70 | 140 | 210 | 350 | |

| Stirring power (Kw) | 1.5 | 3.7 | 5.5 | 11 | 18.5 | 30 | |

| Control panel | Steel-made box for outdoor use | ||||||

| Automatic valve | Electrically-powered | ||||||

| Power supply | 3 phase, AC 220V/380V | ||||||

| Diameter (㎜) | 600 | 850 | 1,150 | 1,600 | 2,000 | 2,600 | |

| Height (㎜) | 2,600 | 2,705 | 3,035 | 3,320 | 3,725 | 4,200 | |

| Weight (kg) | 680 | 935 | 1,550 | 2,650 | 4,250 | 6,000 | |

| Operation weight (kg) | 1,180 | 1,995 | 3,550 | 6,800 | 11,050 | 16,300 | |

| Pipe | Main pip(mm) | 65 | 80 | 100 | 150 | 200 | 250 |

| Drain pipe(mm) | 40 | 50 | 65 | 100 | 125 | 150 | |

| Body material | SS400, STS304 | ||||||

| ※ The specifications are as provided by the supplier and are subject to change in actual design and manufacturing. | |||||||

[ Spray-stirring ]